Story: A Rookie’s Lesson in a Minneapolis Whiteout

He thought five minutes would be enough. A rookie out of the Dakotas, he rolled into a Bloomington yard just as dusk turned to a white wall. The blizzard chewed up I-35 and spat out exhausted drivers looking for a patch of asphalt and a cup of coffee. Our rookie, eager to make his early morning delivery, skipped a thorough engine pretrip inspection, didn’t top off with winterized fuel additives, and parked nose-first against a snow-drifted fence. Overnight temperatures dropped past zero. By dawn, the truck’s batteries were sluggish, the fuel had gelled, and the plow contractor left a berm boxing him in. He tried repeated cold weather starts, then idled to stay warm, forgetting the city’s idling policies and risking a ticket as exhaust vapor pooled under the trailer. He could have avoided it all with a winter driving checklist taped to the dash and a clearer plan for yard parking. In the North, mistakes compound fast. This trucking guide is how not to make them.

HMD Trucking

Plenty of carriers operate in the Twin Cities, but winter separates the outfits that plan from those that hope. Companies like HMD Trucking understand the local curveballs—river bridges that ice first, crosswinds barreling off prairie gaps, and municipal enforcement of winter parking and idling. Their approach highlights a few non-negotiables for winter trucking safety: clear heater policies for when to use bunk heaters versus APUs versus permitted idle windows; practical idling policies that balance emissions rules with driver warmth and engine protection; and simple, enforceable yard parking standards so snow removal, emergency access, and exhaust clearance aren’t left to chance.

Problem-Solution: The Twin Cities’ patchwork of road safety requirements and winter driving hazards can trip up even the seasoned. The problem is not just snow; it’s how fast conditions flip—wet pavement turns to black ice on the Lowry tunnel exit, visibility collapses along the Mississippi valley, and overnight frost welds air lines and door gaskets. The solution is a layered strategy: clear, written policies on heat and idle; crew-level checklists for vehicle maintenance; and yard maps that show where to stage equipment as storms approach.

- Checklist:

- Confirm company heater policies and when heater efficiency checks or APU use is required before idling.

- Review local anti-idle rules and company idling policies; know cold-weather exemptions and proof-of-need protocols.

- Map yard parking lanes designated for plowing; note plug-in points, fuel island access, and emergency routes.

- Carry approved winter driving gear and winter driving equipment; verify trucker preparedness training is up to date.

- Schedule mid-season truck maintenance with a focus on brake system care, tire maintenance, and battery maintenance.

Vehicle Maintenance for Winter Conditions

Problem-Solution: Cold strips performance from every system. It thickens oils, saps batteries, condenses water in the air system, and hides trouble until it’s too late. The solution is simple but disciplined: a stricter maintenance cadence and a winter driving prep routine that turns “maybe later” into “done today.” That means more frequent inspections, strategic use of winterized lubricants, and targeted diagnostics from batteries to brakes, supported by documented charging system tests, alternator performance tests, and ABS system diagnostics.

- Checklist:

- Run a full engine pretrip inspection every shift in active storm cycles.

- Use winterized lubricants and verify drive belt condition before long layovers.

- Document brake system checks and air dryer inspection to limit moisture freeze-ups.

- Complete coolant system care steps, including concentration and pressure checks.

- Confirm exhaust system inspection and tailpipe clearance before overnighting.

Battery and Electrical System

Problem-Solution: A weak battery in October becomes a dead truck in January. Cold slows chemical reactions, punishing marginal batteries and stressing starters. The fix is preventative: battery health checks before the first hard freeze, charging system tests to ensure the alternator is recovering from accessory loads, and planned glow plug maintenance on applicable engines. Tie this to heater efficiency checks for the bunk, and you reduce the need for unnecessary idle just to keep electronics alive.

- Checklist:

- Battery health checks with printouts; replace batteries near end-of-life.

- Charging system tests and alternator performance tests under load.

- Inspect grounds, terminals, and harnesses; clean and protect connections.

- Test block heaters and APUs; verify cold weather starts without repeated cranking.

- Inspect fuses and relays supporting winter driving tips tech: lights, camera heaters, and sensors.

Fuel System and Additives

Problem-Solution: Gelling is the ghost in the tank. Fuel that was fine near freezing can thicken at subzero wind chills, starving the engine. The answer includes proven fuel additives sourced for diesel fuel stability, plus fuel system dryness via regular water-drain intervals. Insulate what you can—fuel tank insulation blankets on select fleets, shielded filter heads—and commit to timely fuel filter replacement. Protect lines where road slush freezes into ice sleeves, and ensure fuel line protection routing is intact.

- Checklist:

- Add anti-gel fuel additives at recommended rates before cold snaps.

- Verify fuel system dryness; drain water separators daily in deep cold.

- Schedule fuel filter replacement earlier than summer intervals.

- Confirm diesel fuel stability specifications with suppliers in winter.

- Use fuel tank insulation or park where wind is blocked, when allowed.

Tires and Chains

Problem-Solution: Traction is your only bargaining chip on glazed ramps and drifting side streets. Worn tread, wrong pressure, or the wrong traction aids turn a controllable slide into a disabled rig. The fix is consistent tire tread depth checks, proper inflation for cold, and a confirmed plan for traction aid usage—from sand tubes to snow chains—chosen for snow chain compatibility with your equipment and routes.

- Checklist:

- Perform tire tread depth checks weekly; rotate or replace as needed.

- Set cold inflation pressures; recheck after major temperature swings.

- Carry snow chains where legal; verify snow chain compatibility and storage.

- Practice installing chains in dry conditions; time yourself.

- Stock traction aid usage options: mats, kitty litter, and shovel.

Brake System

Problem-Solution: Moisture hides in air tanks, valves, and lines, ready to freeze and misbehave. Frozen s-cams and sticky valves make winter braking unpredictable. The fix is an aggressive air dryer inspection schedule, daily purges, and truck-by-truck ABS system diagnostics to catch sensor and tone ring issues that snow and salt accelerate. Add clutch and transmission care—cold fluid checks, linkage inspection—and you reduce driveline shock when roads demand finesse.

- Checklist:

- Daily purges and weekly air dryer inspection; replace cartridges on time.

- Document braking system checks; inspect valves and slack adjusters.

- Run ABS system diagnostics; fix wheel speed sensor faults promptly.

- Monitor clutch and transmission care, especially cables and hydraulics.

- Confirm exhaust system inspection to prevent snowpack obstructions.

Emergency Preparedness

Problem-Solution: In whiteouts on I-94 or lake-effect bursts on Highway 36, your lifeline is what you already loaded. If you slide into a median or sit behind a jackknifed trailer, the wrong gear leaves you cold and invisible. The solution is to build a winter survival kit and an emergency communication plan before the sky turns slate gray.

- Checklist:

- Keep a winter survival kit sized for 24–48 hours: heat, food, visibility, traction.

- Practice emergency preparedness scenarios: breakdown, stuck, medical.

- Document emergency communication procedures and backup systems.

- Review frost protection measures for you and the truck—layers, covers, and blankets.

- Confirm windshield deicing tips and supplies; avoid damage to sensors and wipers.

Winter Survival Kit Essentials

Build it like you’ll need it this week, because in this region, you might. Essentials include winter driving gear—thermal gloves, balaclava, insulated boots—plus high-vis outerwear for roadside work. Stock lights, reflectors, and triangles to manage winter road conditions and keep control of road safety around your disabled unit. Carry a compact shovel, traction mats, and kitty litter. Include spare winterized lubricants, coolant top-off for coolant system care, and fuses. Pack non-perishable calories and water rated for cold. Finally, don’t forget a paper winter driving checklist—a simple, memorable list for trucker safety when stress is high.

- Checklist:

- Thermal PPE and high-visibility apparel.

- Tri-fold shovel, traction mats, sand or litter.

- LED beacons, triangles, and spare batteries.

- Blankets, hand warmers, and a backup power bank.

- Spare fluids: DEF, oil, coolant; basic toolkit and gloves.

Communication Protocols

When the network dips and the snow flies, redundancy wins. Use weather alert systems tied to your routes—NOAA radios, carrier apps, DOT feeds—and keep emergency communication lines simple: dispatch, 911, roadside service, and local yard numbers. Share your route planning notes and ETAs, and when you deviate, say so early. Route risk assessment isn’t a one-time task; it’s continuous, informed by incoming reports and your own windshield.

- Checklist:

- Program weather alert systems for Minnesota corridors and border states.

- Keep a printed contact roster for dispatch, emergency, and towing.

- Test CB and handheld radios; confirm battery backups.

- Practice short, clear emergency communication scripts.

- Log deviations in real time; update route risk assessment as conditions change.

Route Planning and Safety

Problem-Solution: Winter routes in the Twin Cities look fine at noon and treacherous by dinner. The problem lies in overconfidence and under-preparedness. The fix is to integrate route planning and winter driving strategies: leave larger buffers, pick safer fuel stops, and schedule around plow passes. Pair that with safe driving practices that assume the worst until proven otherwise.

- Checklist:

- Pad your schedule for storms; reroute to corridors with frequent plow coverage.

- Choose fuel stops with winterized diesel and good lot maintenance.

- Carry and know your traction aid usage limits.

- Review winter driving tips and winter driving advice before each shift.

- Rehearse winter driving precautions with your team at pre-shift huddles.

Monitoring Weather Conditions

Weather in the Twin Cities arrives like a switch flipped. Use layered intel: DOT cameras, radar, and driver-to-driver texts. Track temperature drops that trigger cold weather truck driving issues such as flash freezing on bridges. Plan around known gust corridors and snow fence gaps west of town. When in doubt, re-evaluate rather than power through.

- Checklist:

- Subscribe to corridor-specific weather alert systems and geofenced notifications.

- Set thresholds for delay decisions: visibility, wind gusts, and road temps.

- Coordinate with dispatch on staggered departures to avoid convoy stacking.

- Maintain a live hazard log of winter road conditions from peer reports.

- Confirm truck stops open/close status during blizzards.

Safe Driving Practices

On snow pack and ice, physics rules. Adopt winter driving strategies that widen safe stopping distances, smooth every input, and prioritize space over speed. Keep lane changes deliberate and minimal. Use engine braking judiciously and watch for overconfident traffic, the real winter driving hazards. Keep your windshield clear with tested windshield deicing tips—correct fluid, warmed wipers, and defroster angles that don’t shock the glass. Cold weather driving rewards patience; winter driving safety tips that sound basic save lives when a gust hits on the river bridge.

- Checklist:

- Double or triple safe stopping distances; reduce speed early.

- Steer, brake, and throttle with micro-inputs; avoid abrupt corrections.

- Favor lower gears on descents; manage traction before the curve.

- Use snow chains only where legal and necessary; remove promptly.

- Scan 15 seconds ahead; treat shaded overpasses as black ice zones.

Parking and Rest Areas

Problem-Solution: The wrong parking choice can ruin a week. If you nose in, you may face a frozen berm. Park under a drift zone, and your exhaust can choke. Idle where prohibited, and a ticket awaits. The solution is policy-first planning: understand parking lot safety protocols, know where plows roll, and respect yard parking maps. Use internal heater policies to minimize idle while still protecting your health, and follow idling policies that account for both legal requirements and real cold.

- Checklist:

- Back-in parking when possible; leave a clear escape line for snow events.

- Park away from snow fencing gaps and drift-prone corners.

- Maintain tailpipe and APU exhaust clearance; do an exhaust system inspection on arrival.

- Follow posted yard parking zones for plow access and emergency lanes.

- Respect posted idling policies; use bunk heater or APU per heater policies.

Heaters, Idling, and Local Rules

Across Minneapolis–St. Paul, anti-idle ordinances exist, with cold-weather exceptions designed for safety. Fleet idling policies typically echo this: idle for diagnostics and extreme cold starts; otherwise, rely on bunk heaters or APUs. Heater policies should specify inspection intervals—heater efficiency checks, fuel line protection for heater feeds, and carbon monoxide alarm testing. If a shutdown is required, follow a brief high-idle warm-down to preempt wet stacking, then let block heaters and coolant system care do their work overnight. Your goal is to balance emissions and comfort with engine health.

- Checklist:

- Test bunk heaters pre-season; verify glow plug maintenance where applicable.

- Inspect heater fuel lines; confirm fuel system dryness for heaters.

- Carry a CO detector; test weekly in winter.

- Use frost protection measures: grille covers as spec’d, insulated curtains.

- Log idle time exceptions and reasoning; photograph temps if needed.

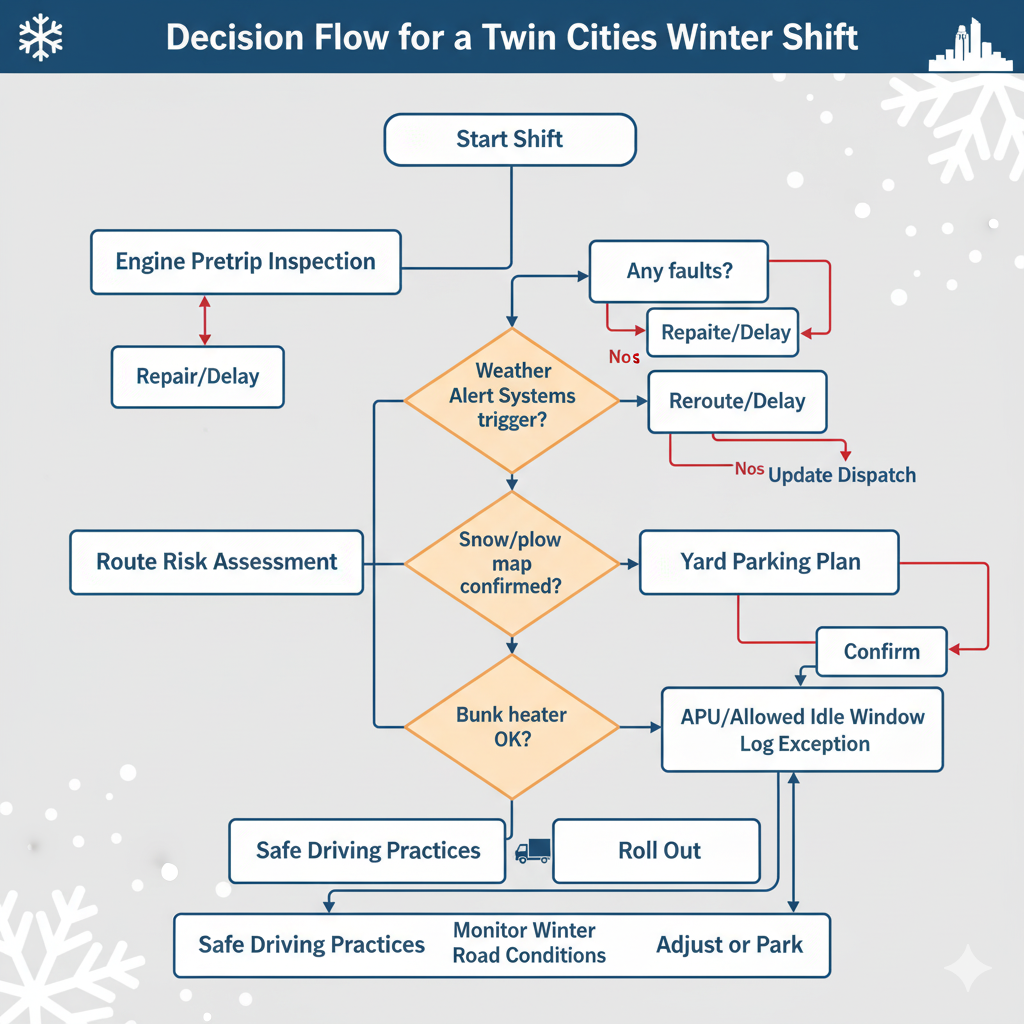

Diagram: Decision Flow for a Twin Cities Winter Shift

Deep Cold Pretrip: What to Touch and Why

When the air hurts to breathe, do the extra five minutes. Start with the front: look for ice ridges that can break loose at speed. Pop the hood and work top to bottom. Coolant system care begins with checking levels, cap integrity, and hose pliability. Verify drive belt condition—cracks or glazing fail faster in the cold. Inspect the alternator mount and run alternator performance tests if voltage readings drift. Check connectors and wiring for brittleness.

Move to the fuel system: confirm fuel filter replacement intervals haven’t slipped; drain separators for fuel system dryness; add fuel additives before the temperature dives. Check for diesel leaks and insulation fit on exposed lines. Verify fuel tank insulation where installed. Cycle the key to run glow plug maintenance routines and test block heaters.

Air and brakes next: drain tanks daily; perform a full air dryer inspection; verify governor cut-in/out; check service and parking brake responses. Complete braking system checks, and if warnings appear, address them now—ABS system diagnostics are faster in the shop than in a ditch. Tires: execute tire tread depth checks; remove embedded debris; set pressures for cold. Confirm snow chain compatibility with your setup and practice a dry run of chain mounting. Driveline: review clutch and transmission care items—linkages, hydraulics, oils—and listen for unusual noises on the first roll.

Local Specifics That Save Time and Trouble

You’re not just fighting winter; you’re working a system. In the Twin Cities, plows prioritize interstates and key arteries, which means side streets and industrial parks lag. Build plans that anticipate late plow passes in outer-ring yards and drifting on open lots. Avoid parking under roof edges that shed ice. Give municipal crews room—a yard that keeps lanes clear for them gets priority returns. Remember that bridges over the Mississippi and Minnesota rivers drop temps fast; approach as if slick even when dry. When in doubt, throttle patience: trucker winter tips that seem conservative often pay out in fewer body shop visits.

For fuel, pick stations with winterized diesel turnover, good lighting, and room for maneuver during snow events. For rest, choose lots that maintain parking lot safety with regular plowing, sand, and marked walkways. On long layovers, favor spots with electrical access and clear exhaust pathways. If you must idle under policy allowances, document conditions and monitor for snow drift that can block vents. Your best tools remain consistency and communication—a routine rooted in truck maintenance and a plan that adapts quickly.

Master List: Quick-Grab Winter Driving Checklist

- Pre-Departure:

- Engine pretrip inspection: fluids, belts, leaks, and mounts.

- Battery health checks; charging system tests under load.

- Fuel additives added; separators drained for fuel system dryness.

- Coolant system care verified; heater efficiency checks completed.

- Windshield deicing tips: fresh fluid, treated blades, clear cowl intake.

- On the Road:

- Route planning with route risk assessment and weather alert systems.

- Winter driving strategies: smooth inputs, longer following gaps.

- Safe stopping distances doubled or tripled in poor traction.

- Use snow chains legally and only as needed; remove ASAP.

- Monitor winter road conditions via DOT cams and peers.

- Parking and Rest:

- Follow yard parking plans; maintain parking lot safety clearances.

- Respect idling policies; apply heater policies and log exceptions.

- Perform exhaust system inspection before resting; clear snow around outlets.

- Stage for plows; avoid drift zones and berm traps.

- Use frost protection measures: curtains, window covers, grille screens as spec’d.

- System-Specific:

- Air dryer inspection and braking system checks; run ABS system diagnostics.

- Clutch and transmission care—cables, fluids, linkages.

- Drive belt condition confirmed; replace suspect belts preemptively.

- Glow plug maintenance and block heater test for cold weather starts.

- Fuel filter replacement scheduled sooner in peak cold.

- Gear and Comms:

- Winter survival kit stocked; winter driving equipment checked.

- Emergency communication tools: radios, chargers, paper contacts.

- High-vis wear, traction aids, and backup lighting ready.

- Road safety triangles and flares accessible.

- Trucker preparedness briefing complete before each storm.

Conclusion: In the North, winter doesn’t forgive mistakes. Whether you’re threading the I-94 commons or backing into a snow-choked dock in Eagan, the right winter driving prep, clear heater policies and idling policies, and disciplined yard parking make the difference between a clean run and a cautionary tale. This is a region that rewards patience, planning, and respect for the cold. Treat every shift as if the sky could shut at any minute—because here, it can.